Industrial doors

Sectional industrial doors (TLP) are the most versatile type of door.

Made of 1 5/8″ thick panels, these doors are insulated, robust, easy to maintain, and safe to operate.

We can manufacture all track types, including custom-made options.

The standard torsion spring offers a lifetime of 25,000 cycles. However, for heavy-duty and super heavy-duty doors, springs with lifetimes of 50,000 and 100,000 cycles are available. For extra-large doors, we can also provide a direct-drive gear system without springs.

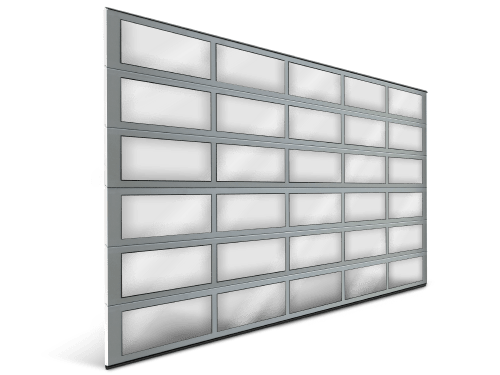

Panels – anodised aluminium frames glazed with double acrylic glass are provided as standard. Aluminium profiles can be painted in any colour, including metallic finishes.

Optionally, you can choose from acrylic, anti-scratch, tinted, matt, polycarbonate, or safety glass.

The white, sandwich-type bottom panel is standard for sectional industrial full-view doors, while a glazed or ‘sandwich-filled’ bottom panel is available as an option.

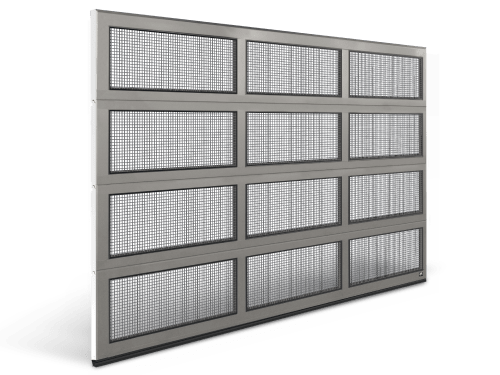

TLT40 sectional doors are designed for premises requiring intensive ventilation, such as underground garages and car parks.

The aluminium frame, with perforated, galvanised, and coated steel sheets or perforated aluminium fillings (3/8″ x 3/8″), ensures the necessary airflow.

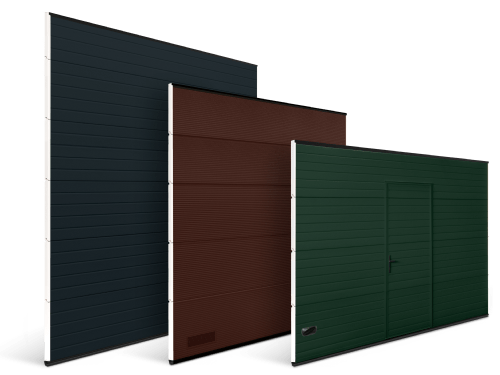

Side hinged industrial doors (ISH2) could be the perfect choice where conventional industrial doors can’t be installed.

Main application areas: agriculture, workshops, storage spaces, big garages.

Insulated and reinforced leaves, steel frame, heavy-duty hinges ensure high durability and perfect performance.

Ryterna specialize in designing and manufacturing large size special doors of various types. Each case is unique.

Sliding telescopic doors, sliding sectional doors, swing doors or direct drive overhead sectional doors could be used for closing large openings.

Each case of each large door is unique, so the right type of door should be chosen to provide good thermal value, functionality, and maintenance-free operation.